How Our Mooring Whips are Made

Many of the products we manufacture such as our dock whips and hose holders are hand crafted from marine grade aluminum . We paint our surfaces using an electrostatic coating process. We pretreat every part by performing an outgassing process in a high heat, vented...

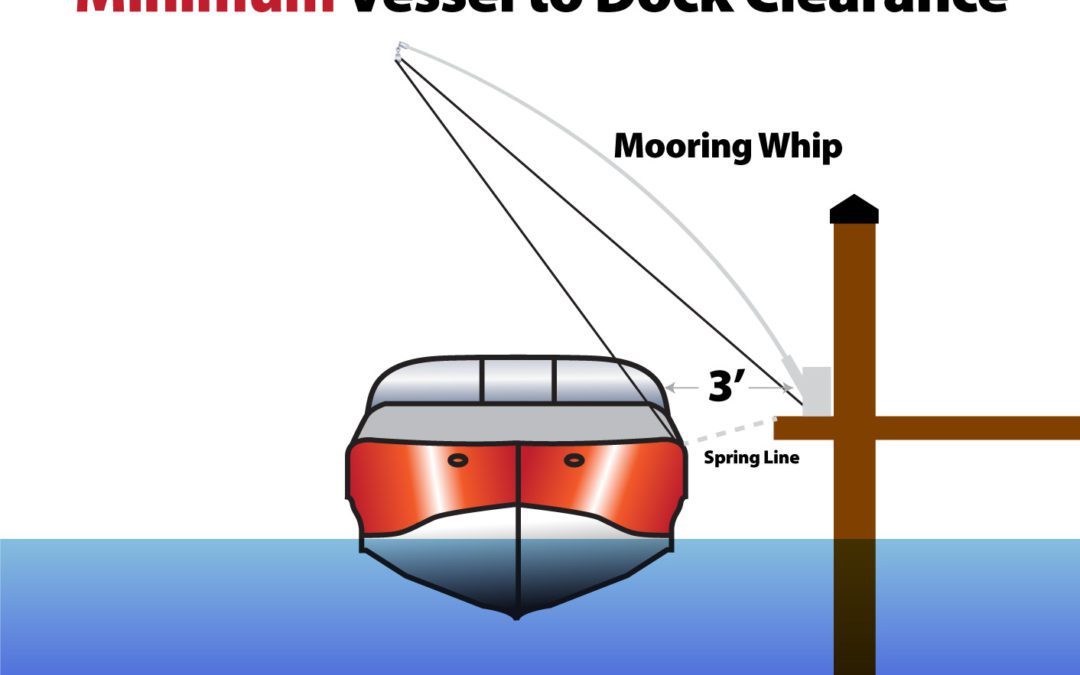

Mooring Whips: Vessel to Dock Clearance

We are often asked “ What is the optimal range of clearance between my boat and the dock?” This is a great question which most whip manufactures don’t openly address. Using deployed standard 14-foot pole sets, the answer is a maximum of 9 feet from the the dock,...

Choosing the Best Mooring Whip for Your Boat Size

When searching for mooring whips many people frequently ask “what size whip do I need for my boat it weighs 10,000 pounds”. This question is not an original customer question. I suspect this question originates from industry advertising, selling various sized mooring...

One Easy Idea Concerning Dock Whips

Dock whips are often used in combination with bumpers, fenders, as well as aquatic quality lines to earn certain the protection of the watercraft. The term pier is employed in the following explanation in a common feeling. Swing moorings additionally called simple or...

Winter Boat Maintenance

It is ok to leave your boat all winter at your dock except; if the water freezes. Here are some winter boat maintenance tips. Freezing water in time can crack your hull. Look what happened to the Peary Expedition. Put your boat as they say on the "hard" blocked...

Taking Care of Rope

To ascertain the line you are using on your boat serves you well, you must take good care of it. Keep Rope Clean Dirt, sand, oil and acids will destroy line on your boat, whether it is natural or synthetic rope. To wash your rope, put it in a mesh bag or pillow case...

Boat Docking Techniques and Tips

Pleasure boats come in a great variety of shapes and sizes with different power options. Docking a boat can be very tricky under normal conditions even more so when interacting with the weather. Here are some boat docking technique tips. There are many variables to...

Mooring Whips

Mooring whips are the practical alternative to marine railways, davits and boat lifts. Fiberglass mooring whips are exceptionally strong, attractive and do not obstruct your waterfront view. Mooring whips work in many applications where no other product will offer...